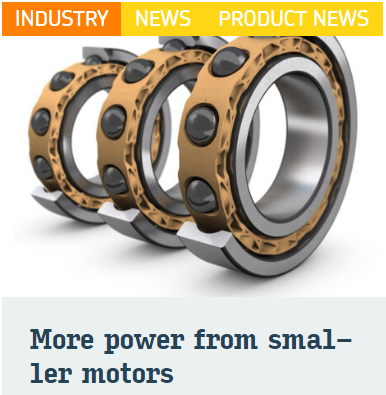

Ceramic rolling elements

Two-piece PEEK cage

The technology that makes it possible

PEEK cage 80% lighter than brass cage boosts the limiting speed

Lower temperatures longer grease life, extend relubrication intervals

A combination to raise reliability and robustness

Ceramic rolling elements

Prevent electric current damage

Enable higher speeds

Extend bearing service life and grease life

Reduce or eliminate false brinelling damage

Reduce wear caused by solid contaminants

Optimized pocket geometry

Homogeneous material

Strong clamping of cage half’s

80% mass reduction

PEEK Cage

More flexibility in your design choices

Get more power from smaller motors with SKF Hybrid Deep Groove Ball Bearings

For operating conditions that demand more

In railway applications, bearings are subjected to increasingly demanding operating conditions. This includes risks of contamination from abrasive dust, poor or inadequate lubrication and vibration. The passage of electric currents can also cause damage or premature failure of standard bearings (rings and rolling elements made of bearing steel). Costly, in terms of machine downtime, lost productivity and increased maintenance needs.

Electrical current damage

Electrical insulation

Resist false brinelling

Vibrations

Long service life in poor lubrication conditions

Extend grease life

Inadequate lubrication

60%

50%

Lower thermal expansion coefficient

Lower friction coefficient

Low adhesion between silicon nitride and steel, no risk of smearing. Less frictional heat with very thin lubricant film

Quieter than ever

The optimized cage design boosts the limiting speed. The two-piece PEEK (polyetheretherketone) and polyamide cage allows a 60% increase on limiting speed compared to a brass cage and a more than 100% increase compared to a single piece polyamide cage.

With its patented design, the new two-piece cage is highly robust, protecting itself from deformation in high speeds. This has also led to less temperature increase during rotating, extending grease life.

The SKF Hybrid Deep Groove Ball Bearings emit even less noise than bearings with a solid brass cage. It is mainly the shape of the cage pocket together with the improved surface roughness and in combination with weight and material that reduces the noise emission of the bearing.

Two - piece PEEK/

Polyamide cage

Two-oiece

Brass cage

Single piece

Polyamide cage

1.6M

ndm

1.0M

ndm

0.8M

ndm

Temperature at marginal lubrication conditions

°C

rpm

Vibration level comparison

Two-piece PEEK/

Polyamide cage

Two-piece

Brass cage

18% lower

vibration

Single piece

Polyamide cage

0.8M

ndm

1.0M

ndm

Two-piece

Brass cage

Two - piece PEEK/

Polyamide cage

1.6M

ndm

Lower temperatures, longer grease life

rpm

°C

Temperature at marginal lubrication conditions

Vibration level comparison

Two-piece PEEK/

Polyamide cage

Two-piece

Brass cage

18% lower

vibration

Optimized cage design boosts the limiting speed

dm = bearing mean diameter (mm)

n = bearing speed

Quieter than ever

Ceramic (silicon nitride) rolling elements

Lower density vs steel, enable higher speeds and frequent starts and stops.

Higher modulus of elasticity vs all steel bearings, increased stiffness

More stable over temperature gradients and more accurate preload/clearance control

60% higher speed

100% higher speed

Two-piece

Brass cage

Single piece

Polyamide cage

Two - piece PEEK/

Polyamide cage

High wear resistance

Abrasive dust

contamination

More flexibility in your design choices

Contact us

Find out more

Download PDF

Read more

Watch the video

Back to top